Supply Chain Management From Xinghongtai

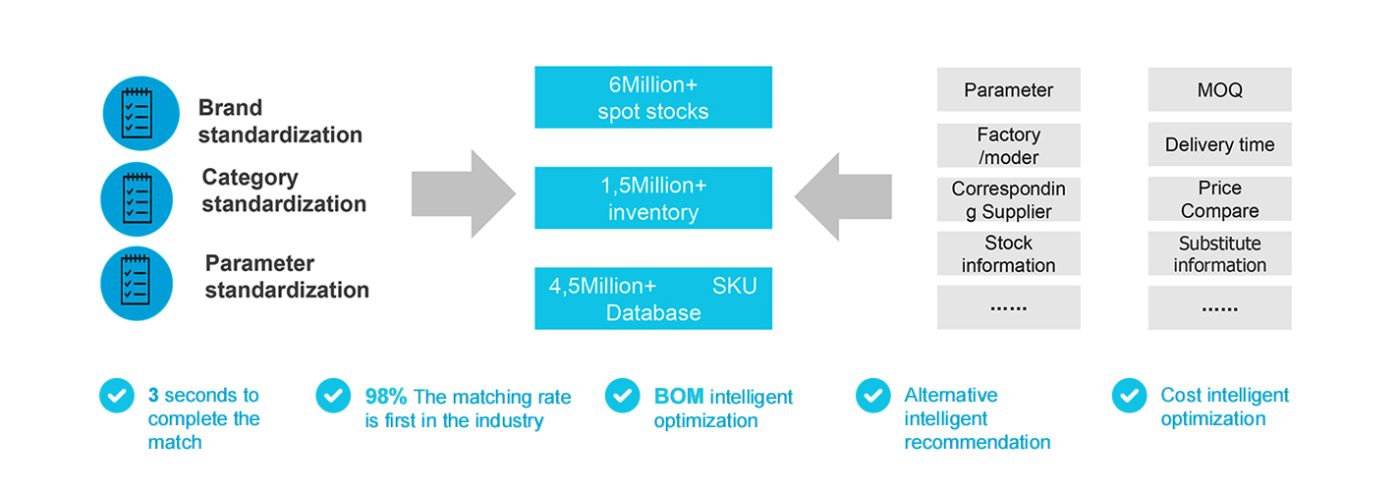

Strong Standardized Database of Component BOM

Xinghongtai has been to establish the industry’s most powerful and broadest coverage of BOM as the core of the standardized databaes.

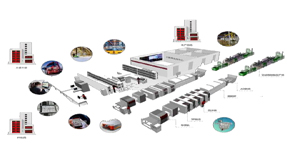

Supply Chain And Production Management

Xinghongtai Company organizes various resources of the enterprise by optimizing each stage of the supply chain such as procurement, planning, production, and logistics, so that the enterprise can save costs and enable the end customer to obtain satisfactory services. It is a value-added service provided for corporate operations, but currently only a few companies value this service.

Planning

At the outset, planning is crucial to allocate all resources in advance to satisfy customer needs and attain the anticipated performance.

Sourcing

we have a complete supply chain system. There are more than 1,500 domestic original factories, we have more than 1,000 overseas original factories, and more than 100 top component agencies.

Intelligent Manufacturing

All manufacturing processes are managed by ERP and WES systems and are barcoded System, you can understand production dynamics, production parameters, and test data in real time.

Shipping Service

Unifying the process of managing customer orders, scheduling deliveries, dispatching goods, issuing invoices to clients, and processing payments.

Characteristics Of Efficient Supply Chain Management

Transparency

Transparency in supply chain management means every link can freely share information, which is critical to managing costs and meeting expectations. It builds trust among supply chain partners, ultimately leading to strong and reliable relationships that support the entire supply chain’s operations.

Timely Communication

Effective communication ensures that every link in the supply chain operates smoothly. This helps prevent numerous issues such as lost goods and dissatisfied customers, allowing businesses to respond quickly even if there are some changes or issues in the supply chain.

Risk Management

During supply chain operations, unexpected situations or new problems will inevitably arise, so the ability to quickly respond to emergencies is crucial. Supply chain management enables the rapid formalization of contingency plans, prompting immediate execution and eventual resolution of the problem.

Analysis and Prediction

With efficient supply chain management, it is possible to examine the current state of enterprises, considering both their strengths and weaknesses. Moreover, it aids in forecasting customer requirements, thereby enabling the preparation of advance production plans. This proactive approach is advantageous for the sustainable growth and development of businesses.

Benefits Of Supply Chain Management

Lower Costs

Through supply chain management, customer needs can be promptly, enabling production that accurately aligns with genuine customer requirements. This helps prevent overproduction, which would otherwise escalate labor and raw material costs. Additionally, it contributes to reducing the expenses associated with inventory management.

Resource Integration

Efficient supply chain management enables the prudent utilization and allocation of resources, such as labor, production equipment, and transportation facilities. This includes scheduling production based on requirements to minimize equipment usage. Ultimately, this leads to a substantial enhancement in value for both the organization and its customers.

Higher Efficiency

Supply chain management aids companies in effectively integrating diverse resources and dynamically adapting to fluctuating market conditions. Concurrently, the sharing of information related to materials, production, logistics, and other aspects optimizes the efficiency of business operations.

Deep Cooperation

In the absence of proper communication, suppliers and distributors may experience delays in receiving up-to-date information, resulting in hindrances to the cooperation process. Efficient supply chain management mitigates such issues by facilitating information exchange and fostering mutual understanding. This conducive environment promotes deeper collaboration among parties.

Related Work Process

Check The Incoming Material Quantity

Storehouse

Smart Storehouse