SMT Assembly:A Basic

1 What is SM

2 How does SMT compare with traditional electronic assembly processes

3 SMT production process

4 Industry changes and future prospects brought about by SMT

5 Why choose XHT

SMT is a technology that has revolutionized the electronic assembly process. It installs electronic components directly on the surface of the circuit board, replacing the traditional through-hole insertion method. Originating in the 1960s, with the rapid development of microelectronics technology and the increasing demand for miniaturization, SMT has rapidly swept the global electronics manufacturing industry with its advantages of high efficiency, precision, and space saving.

1、What is SMT

SMT, Surface Mount Technology, is an advanced electronic assembly technology. To put it simply, electronic components are directly placed on the circuit board at a predetermined position and soldered through reflow soldering or wave soldering instead of the traditional jack insertion method. This technology allows electronic components to be arranged densely and orderly on the surface of the circuit board, greatly reducing the size of electronic equipment and improving integration and reliability.

2、How does SMT compare with traditional electronic assembly processes

The traditional electronic assembly process, THT (Through Hole Technology), involves drilling holes into the circuit board and inserting the components and fixing them by soldering. Although this process has been proven stable and reliable for many years, in the modern technological era that pursues products that are light, thin, short, and highly integrated with functions, problems such as its large space occupation, low production efficiency, and inability to adapt to micro-components have gradually emerged.

SMT cleverly solves the above problems by attaching components directly to the surface of the circuit board and connecting them through reflow soldering. Compared with traditional processes, SMT has the following obvious advantages:

High-density assembly: The size of components is greatly reduced, allowing the circuit board to carry more functional units to meet the needs of product miniaturization;

Improved production efficiency: high degree of automation, shortened production cycle, and effective cost control;

Excellent electrical performance: reduce signal transmission paths, reduce impedance, and improve product stability and performance;

Environmentally friendly: Complying with environmental trends such as lead-free and halogen-free, it is conducive to sustainable development.

Although SMT is superior to THT in many aspects, this does not mean that THT will be completely eliminated. In some specific scenarios, such as components that need to withstand large mechanical stress, or designs that have special requirements for electrical performance, THT still has an irreplaceable position. At the same time, SMT is developing towards higher precision and more complex components, such as micro-pitch packaging technology, three-dimensional stacked packaging, etc. As a result, a hybrid process combining SMT and THT has emerged in modern electronic manufacturing, jointly building a richer and more diverse electronic world.

3、SMT production process

Material preparation

According to the PCBA design plan, the material management link then ensures that the required electronic components are accurate and prepared in advance according to the production sequence.

SMD and welding

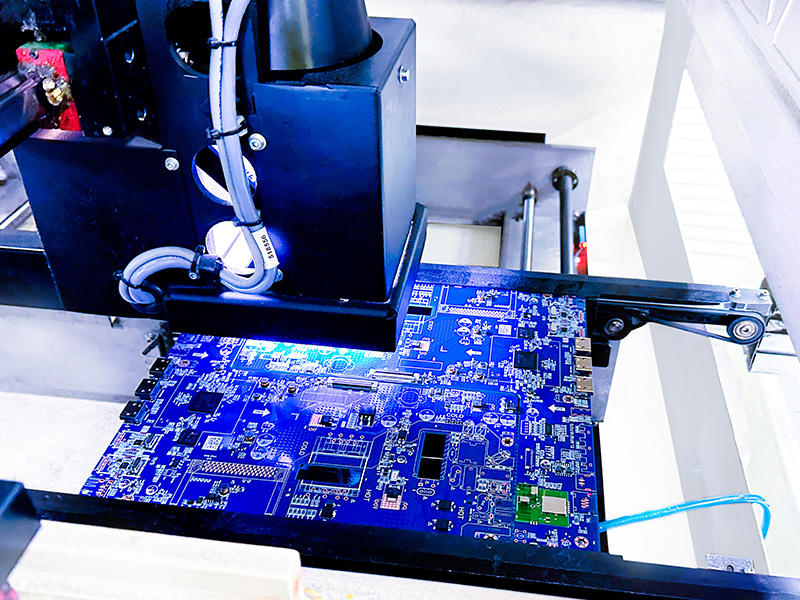

Solder paste printing: First, the circuit board passes through an automatic screen printing machine, and the solder paste is evenly applied to the pre-designed pad positions on the PCB board.

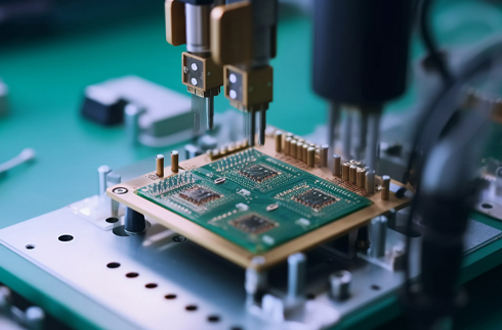

Component placement: Next, the high-speed placement machine uses a high-precision visual recognition system to accurately position tiny resistors, capacitors, integrated circuits and other components on the solder paste.

Reflow soldering: Finally, the completed circuit board is sent to the reflow oven for reflow soldering. Under the action of a precisely controlled temperature curve, the solder paste melts and forms a reliable electrical connection with the components, and solidifies to form a stable solder joint.

3.Quality and testing

After welding, the PCB needs to go through a strict quality control stage, including AOI (Automated Optical Inspection, automatic optical inspection), X-Ray inspection and other high-tech means to ensure that every component is installed correctly and welded well.

4、Industry changes and future prospects brought about by SMT

The popularization of SMT technology has undoubtedly brought unprecedented development opportunities to communication equipment, consumer electronics, automotive electronics, aerospace and other fields. However, challenges and opportunities coexist. While SMT technology continues to improve precision and speed up production rhythm, it also faces many issues such as the increasing difficulty of fine-pitch mounting, optimization of lead-free soldering processes, and how to further integrate into intelligent manufacturing systems.

5、Why choose XHT

XHT has more than 12 SMT production lines, 20 years of experience in the electronics manufacturing industry, and a top engineering team in China. They are very familiar with how to combine SMT and THT electronic mounting processes to solve any product for you. Difficulties encountered during manufacturing. We are also very happy to communicate with our customers and share some experiences in the field of electronic manufacturing. For example, for the above problems, XHT can achieve the minimum placement accuracy of ±0.025mm and has completed the comprehensive optimization of the lead-free soldering process. I believe XHT will be your best partner. Click here–Contact us