PCB Guide (2): Color on PCB Board

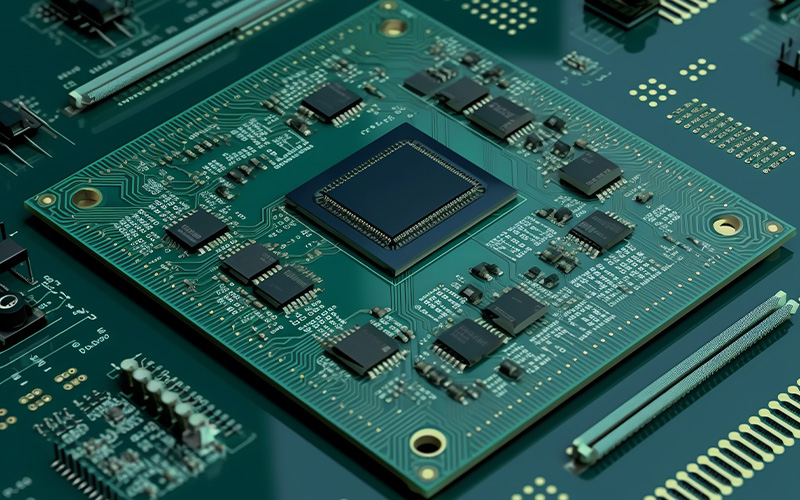

In your daily life, have you ever been curious about the colorful PCB boards inside electronic devices? Why are their colors so diverse, from common green and blue to black, red, and even white, purple and other colors of PCBs. This guide is designed to help you understand PCB more comprehensively.

Why do PCBs have so many colors

First of all, we need to make it clear that the color of the PCB board actually comes from a layer of solder mask (Solder Mask) covering its surface. The main function of this coating is to prevent bridging short circuits during soldering and to protect the circuit from the environment. Different colors result from the addition of different types and concentrations of pigments to the solder mask. The color of the PCB board itself is not a key factor that directly determines its performance and quality. So why do PCBs have so many colors? This is mainly due to various considerations such as functional differentiation, visual beauty, and customer needs.

What is the difference between PCB colors

Green PCB

Green PCB is the most popular color. Therefore, many people have been mistakenly thinking that PCB is green or mostly green. The reason why green PCB boards are widely popular is that the solder resist paint formula used in the early days was mainly green. This color is not only beneficial to the eye comfort of production line operators, but also has a good cost performance. Additionally, a green PCB finish reflects less light, helping to reduce glare.

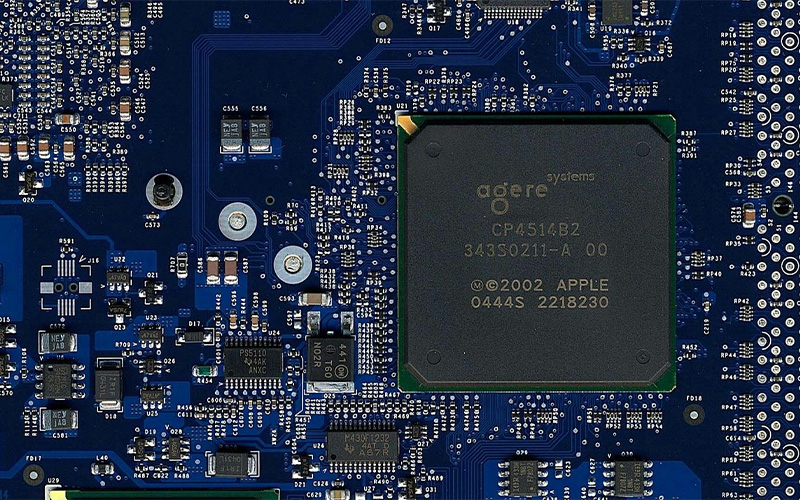

Blue PCB

Blue PCB is considered a thicker board for labeling as it provides significant contrast for screen printing. A blue PCB is better for mounting on an LCD because a blue PCB does not produce sharp contrasting edges and bright background colors.

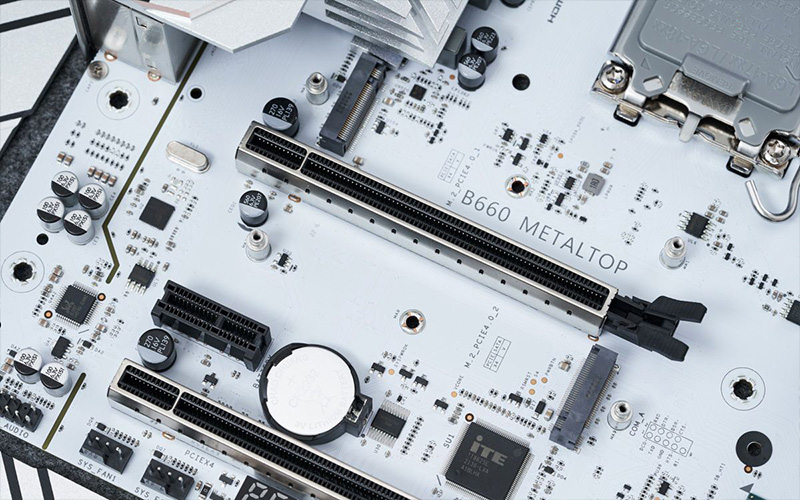

White PCB

White PCBs look high-end in various environments, which makes white PCBs increasingly popular in the market. However, because white PCBs can easily hide traces, higher-level solder mask materials are required during manufacturing, which results in higher costs. So white PCB is still not the first choice.

Black PCB

Black PCB boards are more common in high-end or highly confidential electronic products because of their thicker solder mask, which can better shield the internal circuit structure. However, the main disadvantage of black PCB is similar to that of white PCB, which is that it is easy to hide defects in PCB details. Moreover, the black PCB board is a mixture of cobalt and carbon and has a certain degree of conductivity, so there is a risk of short circuit.

Red PCB

Red PCBs are more common in some specific applications, such as high-end communication equipment, military electronics, etc. Red PCB usually uses high temperature-resistant red photosensitive dye, which has good thermal stability and weather resistance, and is suitable for applications in high temperature and harsh environments.

Purple PCB

Compared with PCBs of other colors, the cost of purple PCB is often higher. This depends on the fact that the solder mask material used in the purple PCB board is relatively unique, and its raw material acquisition and manufacturing process may be more complicated.

Why will green PCB become mainstream

Facilitates machine inspection

The copper lines on the green background are clearly visible, which facilitates quality inspection and later maintenance during the production process. Even in front of high-precision automatic optical inspection equipment, the green background provides good contrast, making subtle line defects visible at a glance.

Facilitates quality control

Green is a comfortable color for the human eye and will not cause visual fatigue in a long-term working environment. This is especially important for maintenance personnel who require delicate operations, greatly improving work efficiency and accuracy.

cut costs

Compared with other colors, the production process of green solder resist paint is mature and the cost of raw materials is lower.

Easy to recycle

Green PCB waste boards will not release toxic gases when recycled at high temperatures. Other PCB colors, such as blue and black, are doped with cobalt and carbon respectively, as they are less conductive and pose a risk of short circuits.

How can XHT help you

XHT will have an in-depth understanding of your needs. Whether it is for special application scenarios such as high-density integrated design, high-frequency signal transmission or high-temperature working environment, the XHT team can conduct in-depth analysis based on your specific project needs to ensure the recommended PCB type, layer The numerical structure, material selection and appearance color can all be perfectly matched. Click here–Contact us.