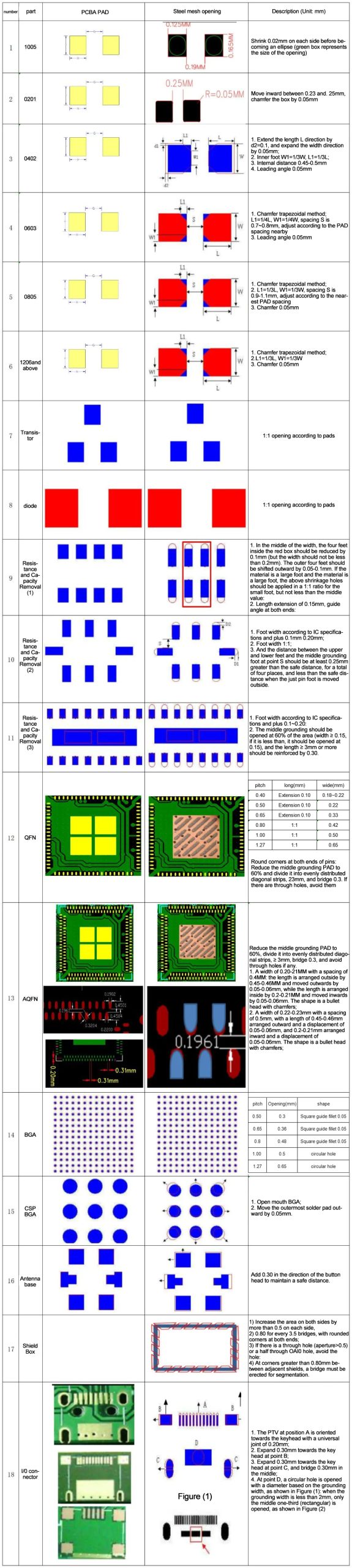

Commonly used component pad opening designs

- Three-dimensional dimensions of steel mesh openings

- The area of the opening

- Control requirements for the ratio of solder paste volume to solder volume

- Requirements for special substrates

Standards for steel mesh openings

In order to ensure ideal soldering effect and soldering quality, the design of component openings should follow a strict set of standards. Specific requirements are as follows:

Three-dimensional dimensions of steel mesh openings

The three-dimensional dimensions of the opening of the steel mesh (length L, width W, and thickness H) must be greater than the product of the corresponding three-dimensional dimensions of the pad (length L pad, width W pad) and half the thickness h of the component foot, that is:

L × W × H > L pad × W pad × h/2

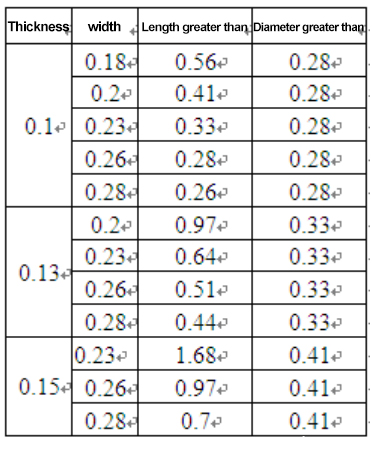

Based on this principle, we set the following minimum threshold for opening width for steel mesh of different thicknesses:

0.15mm thick steel mesh:Its opening width W should be greater than 0.23mm to meet good tin flow and solder coverage.

0.13mm thick steel mesh: The corresponding opening width must be greater than 0.18mm to ensure that the solder can fully fill the gap between the pad and the component feet to achieve stable welding.

0.1mm thick steel mesh: Its opening width must be at least 0.16mm to ensure that the solder can effectively penetrate into small spaces and form high-quality solder joints.

The area of the opening

In stencil design, ensuring that the opening area ratio (the ratio of the stencil opening area to the stencil opening hole wall area) is greater than 0.66 is a key criterion to optimize welding quality and production efficiency. The ratio formula is expressed as follows:

Opening area ratio = Steel mesh opening area / Steel mesh opening hole wall area ≥ 0.66

Following this criterion, when the width and thickness parameters of the steel mesh opening are known, the appropriate opening length or diameter can be calculated or selected accordingly. The following are some typical parameter combinations (unit: mm), and corresponding opening length or diameter setting suggestions:

Control requirements for the ratio of solder paste volume to solder volume

In order to achieve excellent tin application and ensure sufficient solder volume, component opening design should follow specific solder paste to solder volume ratio standards. Specific requirements are as follows

Before reflow soldering, the initial volume of solder paste filled in the component opening should be at least twice the volume of solder formed after reflow soldering, that is:

Solder paste volume before reflow / Solder volume after reflow ≥ 2

Requirements for special substrates

When dealing with special products, special care must be taken in the design of the stencil opening to prevent short circuits between solder pastes after widening the opening. For this reason, it is necessary to ensure that the widened solder paste gap is at least four times the thickness of the solder paste. The following is the reference standard for opening size based on 0.10mm thick solder paste.

For example, when designing to widen the stencil openings of large pins and large spacing components on aluminum substrates, the minimum solder paste gap between adjacent openings should be set to 4 times the solder paste thickness. Taking 0.10mm thick solder paste as an example, the corresponding minimum solder paste gap should be 0.40mm.

About us

Xinghongtai focuses on providing one-stop electronic manufacturing solutions such as SMT chip processing, PCBA processing, and DIP/AI plug-in processing. And it has successfully served customers in multiple industries such as main core boards, industrial customized power boards, optoelectronic products, medical electronics, white goods, FPCB, security, and automobiles. The company has been deeply involved in the industry for many years and has accumulated rich experience and advanced technology. It enjoys a high market reputation especially in China. learn more