Analytical Electronics Manufacturing Services (EMS)

1 Basic definition of electronic manufacturing services (EMS)

2 Electronic Manufacturing Services(EMS) and Original Equipment Manufacturer (OEM)

3 Practical applications of electronic manufacturing services (EMS)

4 Advantages of Electronic Manufacturing Services (EMS)

5 Trends in Electronic Manufacturing Services (EMS)

6 How to choose an EMS company

1. Basic definition of electronic manufacturing services (EMS)

Electronic manufacturing services (EMS) is a professional outsourcing service model that covers product design, raw material procurement, PCB assembly (such as SMT patches, THT plug-ins, etc.), finished product testing, quality control, logistics distribution, and after-sales service Wait for the whole process. EMS companies rely on their advanced production equipment, professional engineering and technical teams and strict quality management systems to provide electronic product manufacturers with one-stop, end-to-end production solutions.

In the rapidly changing global market, the Electronics Manufacturing Services (EMS) industry is undergoing profound evolution at an unprecedented speed. As a leading electronics manufacturer, Xinghongtai is fortunate to witness and participate in this change and witness how electronic manufacturing services (EMS) play a vital role in the electronics value chain. In this article, we will tell you about the differences, practical applications, advantages and development trends of the EMS industry, as well as considerations for choosing an outsourcing company.

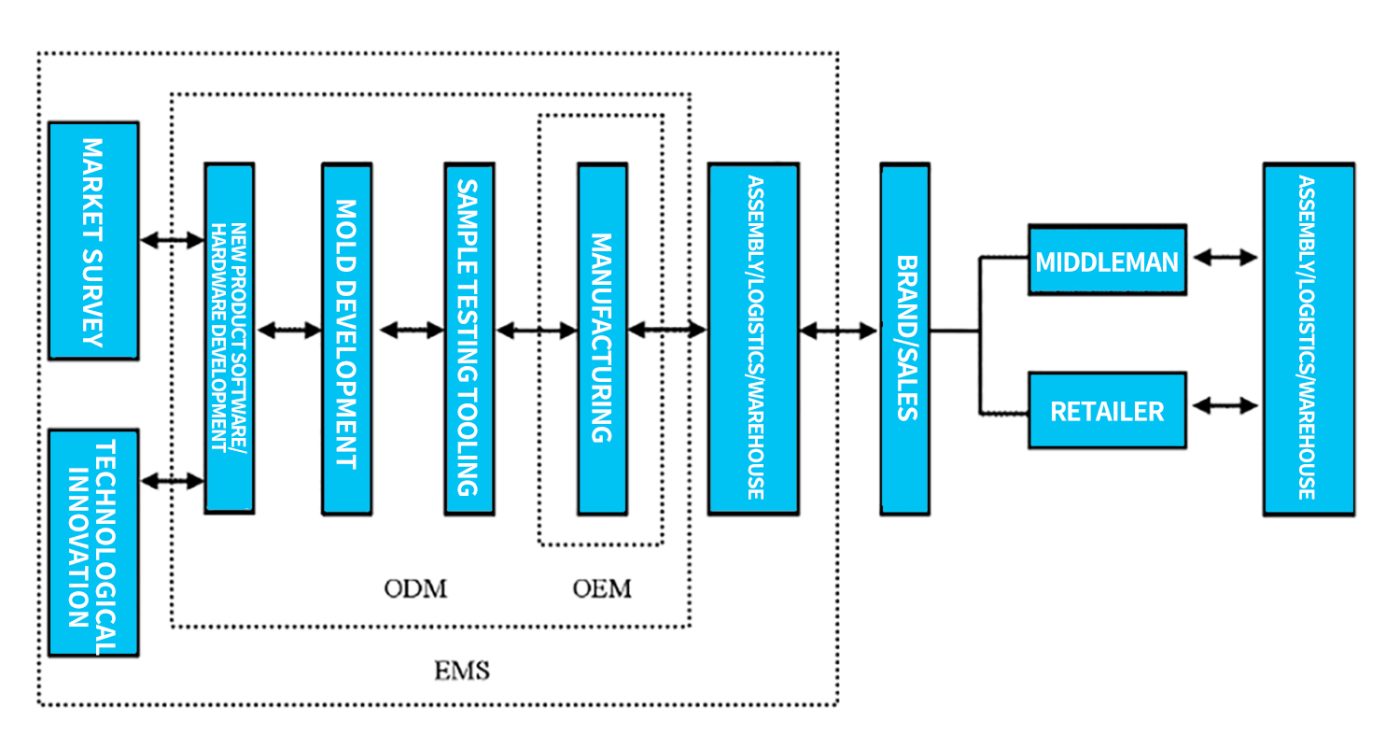

2. Electronic Manufacturing Services (EMS) and Original Equipment Manufacturer (OEM)

Electronic Manufacturing Services (EMS)

Focusing on providing one-stop solutions, from product design optimization, material procurement to production and manufacturing, testing and verification, logistics and distribution, customers only need to focus on product R&D, design and marketing. Under this model, electronic manufacturing services (EMS) companies help customers reduce manufacturing costs, shorten time to market, and respond quickly to changes in market demand through large-scale operations and professional management.

Original Equipment Manufacturer (OEM)

Usually they have independent intellectual property rights, are responsible for the overall design and development of products, and produce OEM products for customers under their own brands or according to contract requirements. OEM focuses more on the R&D and innovation of core technologies and strictly controls product quality. At the same time, it achieves mass production of products by establishing its own production lines and supply chain systems.

All in all, OEM companies focus on technology research and development and brand building, and create competitive product lines through continuous innovation and accumulation of technology patents, thereby establishing a brand image in the market and consolidating their industry position. EMS companies pay more attention to flexible and efficient service capabilities and strong resource integration capabilities. They can carry out customized production according to different customer needs, effectively respond to the production needs of multiple varieties, small batches to large batches, help enterprises reduce capital investment and improve operational efficiency.

Nowadays, many large Original Equipment Manufacturers (OEM) will outsource some non-core production links to professional electronic manufacturing services (EMS) companies, thereby focusing on product research and development, market development and brand image building. Currently, the global economic system is facing profound changes and reconstruction. More and more OEMs choose to cooperate with electronic manufacturing services (EMS) companies to share the value of the industrial chain and realize a “symbiotic economy.” This cooperation model enables both parties to form joint efforts in R&D innovation, cost control, quality assurance and market response speed to jointly cope with the challenges of the increasingly complex market environment.

3. Practical applications of electronic manufacturing services (EMS)

What services do electronic manufacturing services (EMS) companies provide?

Design and product development

From the beginning of the product idea, EMS companies begin to intervene, providing professional circuit design, PCB layout, structural design, rapid prototyping and other services to help you quickly transform your innovative ideas into physical prototypes and achieve preliminary verification of your products.

Raw material procurement and management

EMS companies have a large supplier network and an efficient material management system. They can help you source high-quality raw materials around the world, ensure timely supply, and at the same time reduce costs through centralized procurement to maximize the use of resources.

PCB Assembly(PCBA)

EMS company has advanced production equipment and first-class production lines, and can provide a series of PCBA production and finished product assembly services including SMT surface mounting technology, THT plug-in welding, complete machine assembly, etc. Through strict quality management systems and lean production concepts, we ensure that every product reaches high quality standards.

Test and verify

For different types of electronic products, EMS companies will conduct strict functional tests, performance tests, environmental reliability tests, etc. to ensure that the various indicators of the products comply with international or industry standards, effectively reducing the rate of defective products and after-sales problems. At the same time, EMS companies are familiar with the product certification requirements of various countries and regions, such as CE, UL, FCC, etc., and can assist customers in completing relevant certification processes to ensure that products successfully enter the target market.

Logistics and after-sales

EMS companies also provide complete logistics and distribution solutions to ensure that products are delivered on time and with high quality to customers around the world. In addition, they can also provide corresponding services for after-sales maintenance and technical support needs to protect the long-term interests of customers.

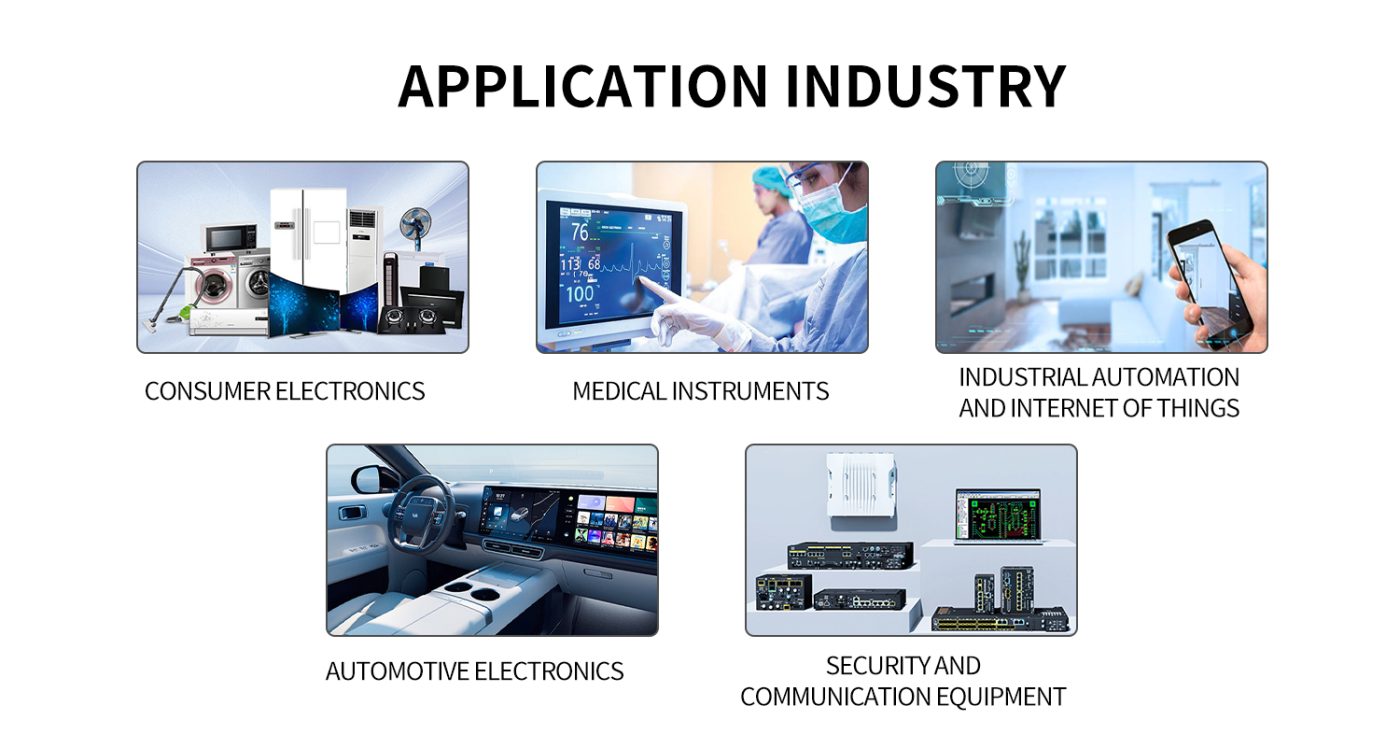

Application industry

Consumer electronics field

The consumer electronics industry is changing rapidly, with rapid product iteration and diverse market demands. With its rapid response capabilities, sophisticated production technology and strict quality control system, EMS companies help companies achieve seamless docking from product development, prototype production to mass production, ensuring the high efficiency of smart wearable devices, smartphones, tablets and other products. Listed.

Medical instruments

Medical electronic equipment has extremely high requirements for accuracy, safety and reliability. By providing a professional clean room environment, strict quality management processes and customized production plans, EMS companies have successfully empowered product development and manufacturing in the fields of medical imaging equipment, vital signs monitoring instruments, implantable medical devices and other fields, significantly improving medical care. The technical level and service quality of the industry.

Industrial Automation and Internet of Things (IoT)

In the era of Industry 4.0, the trend of intelligence and networking has prompted the increasing demand for electronic manufacturing services in the industrial automation and Internet of Things industries. EMS companies can not only complete complex circuit board assembly and system integration, but also provide integrated solutions covering hardware design optimization and software development support, helping companies achieve breakthrough development in intelligent manufacturing, energy management, logistics monitoring, etc.

vehicle electronics

With the development of new energy vehicles and intelligent driving technology, the automotive electronics industry is undergoing an unprecedented change. EMS Company relies on its advanced in-vehicle electronic module manufacturing capabilities, strict quality management system and supply chain synergy advantages to help traditional cars transform into electrification and intelligence, and jointly shape a new pattern of future travel..

Security and communication equipment

In high-tech fields such as security monitoring and wireless communications, EMS companies provide highly integrated and stable electronic product manufacturing services, which effectively guarantee the stable operation of base station construction, communication transmission equipment, and intelligent security systems, and provide strong support for building smart cities. Strong technical support.

4. Advantages of Electronic Manufacturing Services (EMS)

Powerful supply chain management and resource integration

Electronic manufacturing services (EMS) companies can effectively reduce raw material costs and ensure stable material supply through global procurement networks and rich supplier resources. At the same time, its powerful supply chain management system makes the entire process from raw materials to finished products transparent and controllable, greatly improving production efficiency and the response speed of the overall supply chain.

Advanced production technology and resource sharing

Electronic Manufacturing Services (EMS) has first-class production equipment and technical teams. Electronic manufacturing companies have demonstrated extremely high craftsmanship and quality standards in circuit board design, SMT patches, THT plug-ins, welding assembly, etc. Customers can focus on their own core technology research and development and brand building by sharing EMS’s technical resources, thereby improving the technology and quality of their products.

Cost optimization and risk diversification

Through large-scale operations and professional supply chain management, EMS can effectively reduce raw material costs, while reducing customers’ fixed asset investment and operational management burden. In addition, with its extensive supplier network and global layout, EMS can better respond to external risks such as raw material price fluctuations and changes in international trade policies, and ensure the stability and continuity of production.

Quality control and assurance

Electronic Manufacturing Services (EMS) companies follow strict international standards, such as ISO9001, ISO14001, etc., and have established complete product quality and environmental protection management systems. They have professional quality inspection teams and advanced testing equipment to ensure that products meet global market access requirements and reduce the risk of brand loss caused by product quality problems.

5. Trends in Electronic Manufacturing Services (EMS)

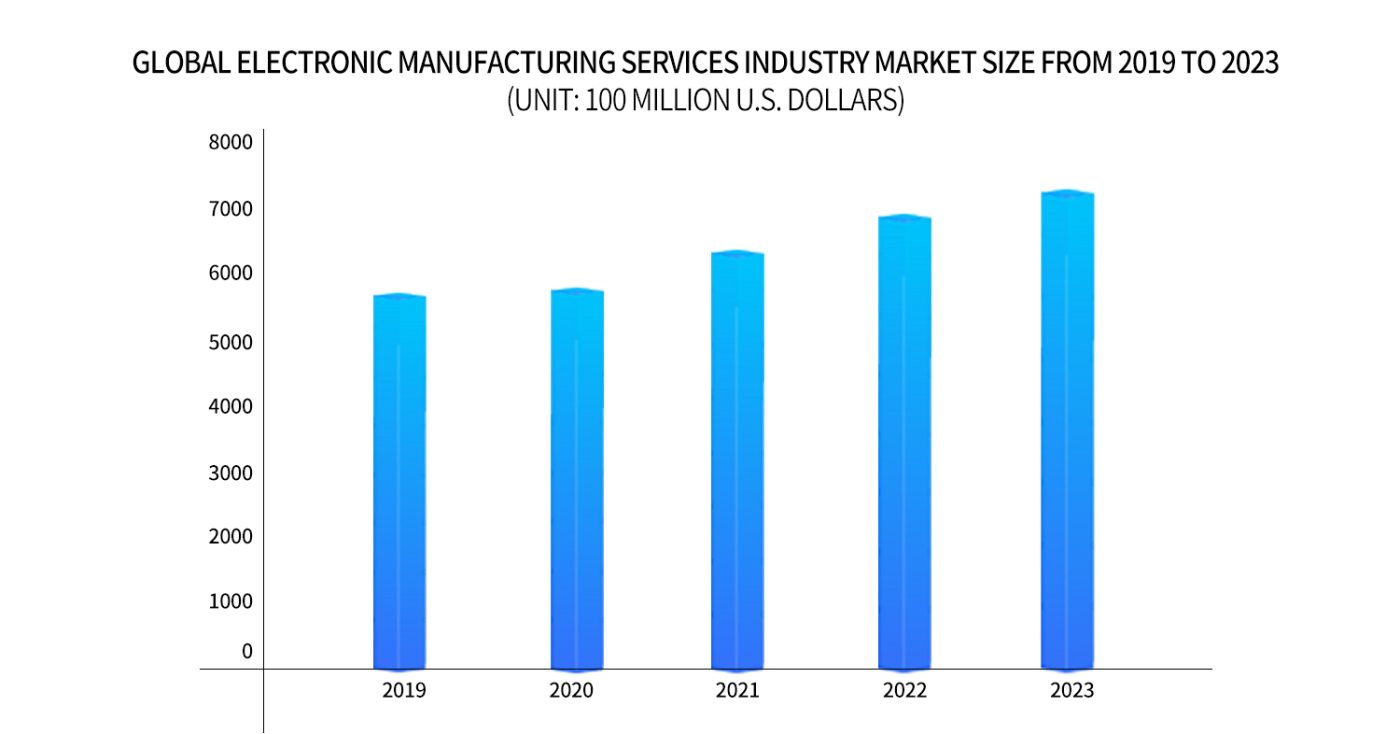

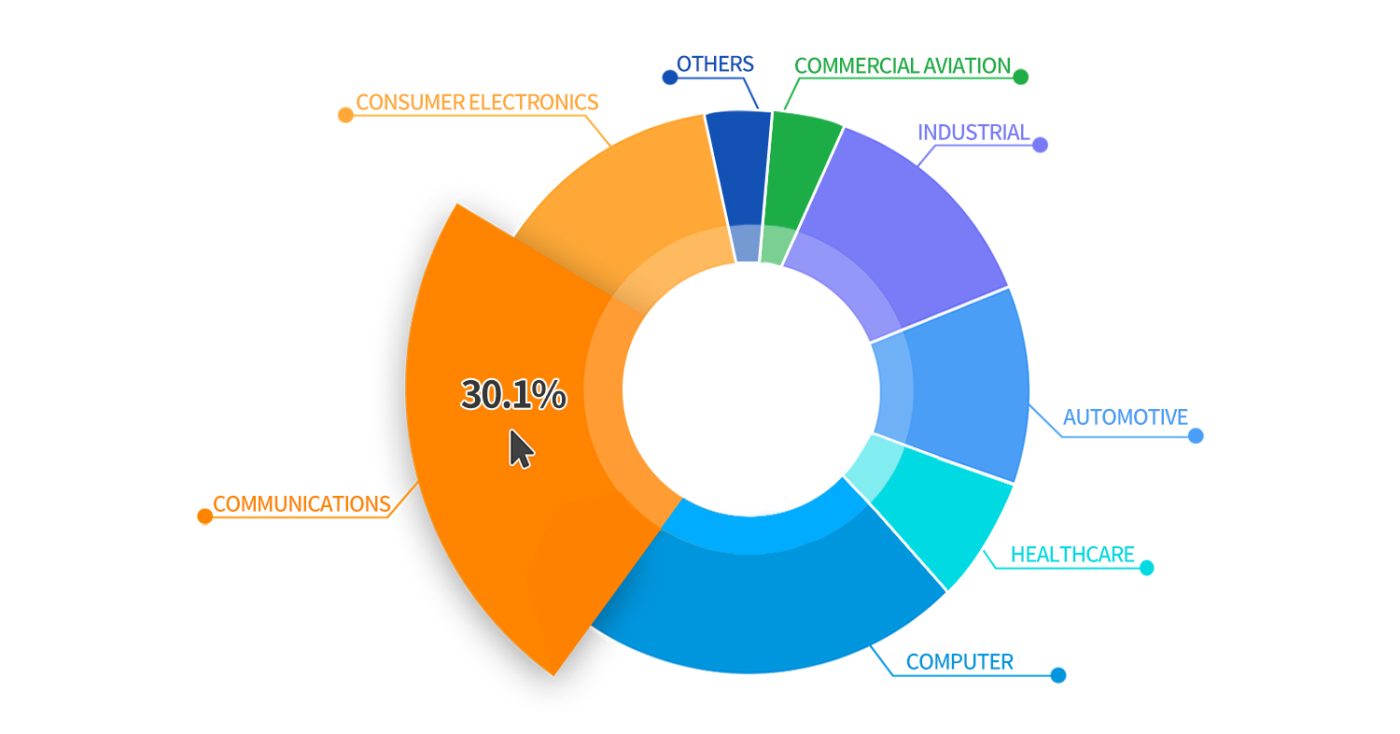

According to the latest data released by New Venture Research, an authoritative research institution, the global EMS market size has reached a staggering US$678.4 billion in 2023, and is expected to reach US$946.5 billion in 2026, with a compound annual growth rate (CAGR) of as high as 7% during the period.

The Asia-Pacific region is the growth engine of the global EMS market, accounting for the largest share of the global EMS market, especially represented by China, Japan, South Korea and Southeast Asian countries. Benefiting from large-scale production bases, low-cost labor resources, a complete supply chain system, and a huge domestic demand market, EMS companies in the Asia-Pacific region have performed outstandingly in scale expansion and technological innovation, and have become the center of global electronics manufacturing. North America, as an important source of global technological innovation, continues to promote industry innovation and development with its advanced technology research and development capabilities. As some countries in the Middle East, Africa, and South America have increased their investment in infrastructure construction, energy development, smart cities and other projects, they have begun to pay attention to the development of local manufacturing. Coupled with their rich natural resources and broad consumer markets, they have attracted more and more people. More and more international EMS companies are setting up production bases or seeking cooperation opportunities here.

As people’s demand for consumer electronics such as smartphones and wearable devices increases, the demand for advanced vehicle electronic equipment, intelligent driving systems and core components of new energy vehicles has exploded. This has provided a steady flow of orders to the EMS market, and more participants have joined the industry. This fierce competition will further prompt EMS companies to continuously improve their standards in production processes, quality control, environmental responsibility, etc., and promote the entire industry. standardization process to ensure the healthy and sustainable development of the industry.

6. How to choose an EMS company?

1.Does it have mature production capabilities?

The first condition for evaluating an EMS company is whether it has mature production lines and advanced production equipment. Examine whether it has a full range of production technologies such as SMT patches, THT plug-ins, and automated assembly, and pay attention to its actual performance in quality control, production efficiency, and yield rate. At the same time, understand its ability to accept and apply new materials and new processes to ensure its competitiveness in the trend of technological innovation.

2. Does it meet all industry standards?

Compliance is the basis of cooperation. High-quality EMS companies should strictly implement internationally or industry-recognized quality management systems, such as ISO9001, IATF16949, etc., and should also comply with environmental regulations such as RoHS and REACH, as well as product certification standards such as UL and CE. These all reflect the company’s rigorous attitude in terms of quality assurance, environmental protection and market access.

3. Does it meet the EMS market demand of “small batch, multiple varieties”?

In a rapidly changing market environment, rapid product iteration and revision are the norm. The ideal EMS partner will be highly flexible, able to quickly adjust production lines and effectively handle your product changes and revision requests without affecting existing production.

4. Do you have a life cycle management and anti-counterfeiting system?

Excellent EMS service providers should not only focus on the manufacturing process, but also provide services covering the entire product life cycle. They should establish a complete product life cycle management system to provide precise support from design and development, material procurement, production and manufacturing to after-sales service. In addition, the use of effective anti-counterfeiting technology and tracking systems to ensure product safety and credibility is also an important dimension to measure the overall strength of an EMS company.

At last

In this ever-changing electronics industry market, XHT keeps pace with the times, drives development with innovation, and constantly breaks through the boundaries of traditional manufacturing. Create a new electronic manufacturing model for you that takes into account efficient production and environmental friendliness. If you are looking for a partner, I believe that XHT will be your best choice.

Hot Post